Self-actuating pressure control valves serve to maintain an adjustable set-point pressure within certain levels in pipelines or vessels (tanks). They are self-actuating i.e. do not feature additional auxiliary energy, and are preferably used to control the pressure of fluids, gases and vapours in industrial, foodstuffs and pharmaceutical plants. Self-actuating pressure control valves are the most uncomplicated and cheapest controllers available. The main advantage associated with this type of valve is that no additional auxiliary energy is necessary for moving the actuator, thus boosting the realisation of simple pressure control systems at relatively low cost.

Self-actuating pressure control valves are pure P-controllers (proportional controllers). In conjunction with a random controlled section, P-controllers always display permanent deviation from the preset reference value which is mainly determined by the size of the P-range (proportional range). Self-actuating pressure control valves are primarily designed as pressure reducing valves and primary pressure controllers. These, however, are complemented by a range of differential pressure controllers and vacuum control valves. Depending upon the pressure range of the control valves, either spring or air loaded membrane or piston controlled proportional controllers are used. Because of the larger membrane effective surface areas achievable, the membrane controlled proportional valves are employed for very small pressures (millibars), and the piston controlled valves at pressures ranging from several tenths of a bar up to 80 bars.

Niezgodka GmbH supply tailor-made Pressure Reducing Valves, Sustaining Valves (Initial Pressure Controllers), Vacuum Control Valves and Differential Pressure Control Valves for various fields of industry, including industrial plant engineering and construction, oil and gas production, the foodstuffs and pharmaceuticals industries, ship operations technology and transport container construction. See the full range of Niezgodka valves that Flowstar is able to supply on the dedicated Niezgodka page on our website.

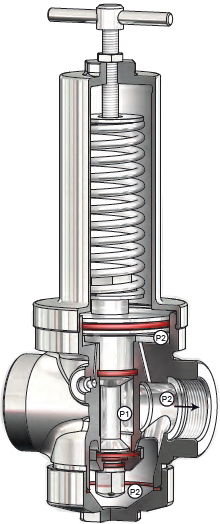

Niezgodka Pressure Reducing Valves

Pressure-Reducing-Valves types 70.2, 71.2, 74.2, 75.2 for industrial plants and types 70 series SKM, SKK, SKS, SKG, SMK and SMS for the foodstuffs and pharmaceutical industries are primary pressure-relieved proportional controllers and, depending on the minimum pressure range, either spring loaded or air loaded piston or membrane-controlled. They are used to keep the outlet pressure P2 at a constant adjustable reference value with fluctuating primary pressures P1 and fluctuating flow volumes.

- Nominal pressures: PN 1.6 to PN 180

- Connections: G 1/8 to G 2 ½ or DN 8 to DN 100

- Process connections: normal commercial thread, screw, clamp or flange connections

- Materials: 1.4301, 1.4571, 1.4404, 1.4435, as well as elastomer and thermoplastic element seals

- Kvs values: 0.63 to 53 m³/h

- Minimum pressure range P2: 0.005 bars to max. 80 bars

- Flow mediums: gases, steam and liquids

Above: Niezgodka Pressure Reducing Valve

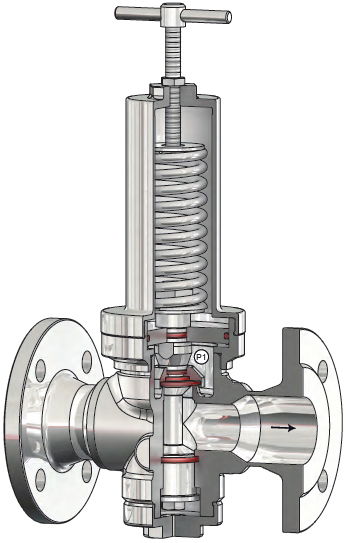

Niezgodka Sustaining Valves (Initial Pressure Controller)

Initial-Pressure-Controller of the types 80.2, 81.2, 84.2, 85.2 for industrial plant and type 80 of the series SKK, SKS, SMK and SMS for foodstuffs and pharmaceutical equipment are vac pressure relieved and depending on the primary pressure range either piston or membrane controlled proportional valves with spring load or optionally air load. They are used to control the Primary Pressure P1 at a pre-determined Set point. These valves do not control the downstream P2 pressure as in the case of Pressure Reducing Valves.

- Nominal pressures: PN 1.6 to PN 180

- Connections: G 1/4 to G 2 ½ or DN 8 to DN 80

- Process connections: normal commercial thread, screw, clamp or flange connections

- Materials: 1.4301, 1.4571, 1.4404, 1.4435, as well as elastomer and thermoplastic element seals

- Kvs values: 1.2 to 28.5 m³/h

- Primary pressure ranges P2: 0.005 bars to max. 60 bars

- Flow mediums: gases, steam and liquids

Above: Niezgodka Sustaining Valve (Initial Pressure Controller)

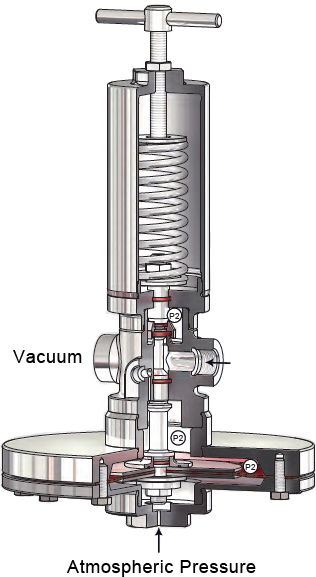

Niezgodka Vacuum Control Valves

Vacuum-Control-Valves for industrial, foodstuffs and pharmaceutical plant are either piston or membrane controlled proportional valves with spring loading, depending upon the vacuum range. They are used to keep the vacuum pressure P2 at a constant adjustable reference value with fluctuating flow volumes. Vacuum controllers are special design differential pressure control valves with an opening function.

- Nominal pressures: PN 1.6 to PN 16

- Connections: G 1/4 to G 2 ½ or DN 10 to DN 80

- Process connections: normal commercial thread, screw, clamp or flange connections

- Materials: 1.4301, 1.4571, 1.4404, 1.4435, as well as elastomer and thermoplastic element seals

- Kvs values: 1.2 to 28.5 m³/h

- Primary pressure ranges P2: -0.005 bars to -0.95 bars

- Flow mediums: gases, steam

Above: Niezgodka Vacuum Control Valve

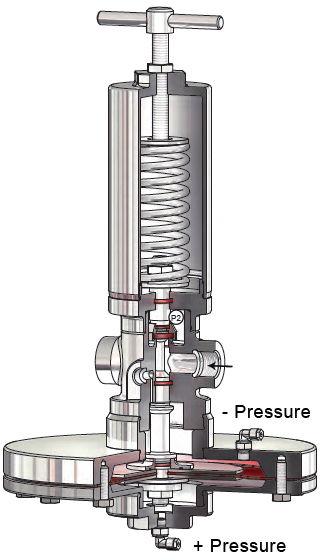

Niezgodka Differential Pressure Control Valves

Differential pressure control valves for industrial, foodstuffs and pharmaceutical plants are fully relieved either piston or membrane control proportional valves, and spring loaded depending on the differential pressure range. They are used to keep the differential pressure ΔP at a constant adjustable reference value at fluctuating primary pressures P1, fluctuating outlet pressures P2 or fluctuating flow volumes. Differential pressure control valves are based on pressure reducing valve and primary pressure control valve design and feature a closing function (closing on increasing differential pressure) or opening function (opening on increasing differential pressure). In this case, the piston plate or membrane area is sealed off from the flow medium and the spring hood made pressure tight. The (+) pressure and the (-) pressure are directed by means of screw connections to one side of the piston plate or membrane. The (-) pressure must always be connected to the spring side.

- Nominal pressures: PN 1.6 to PN 16

- Connections: G 1/4 to G 2 ½ or DN 10 to DN 80

- Process connections: normal commercial thread, screw, clamp or flange connections

- Materials: 1.4301, 1.4571, 1.4404, 1.4435, as well as elastomer and thermoplastic element seals

- Kvs values: 1.2 to 28.5 m³/h

- Primary pressure ranges P2: 0.005 bars to max. 8 bars

- Flow mediums: gases, vapours and fluids

Above: Niezgodka Differential Pressure Control Valve

For further help with these products please contact us on +44 (0)1482 601030 or email sales@flowstar.co.uk.