Because the UK's water supply is such a high quality and suitable for human consumption, it is important that all measures are taken to maintain the water quality. Backflow preventers are one way to do this as it ensures that water contamination of any kind is kept to a certain location, piece of equipment or pipework. Many devices found in the home have backflow prevention built in as standard, since they have an airgap between the supplying pipe and what it supplies. i.e. a tap has an airgap to whatever it feeds, a loft tank has an airgap between the ball float valve and the loft tank, a toilet cistern has an airgap again between the float valve and the cistern tank, finally many modern hose pipes have a check valve (one-way valve) built into the Hozelock style connector at one end.

The current Water regulations were introduced in 1999 in England and Wales and in 2000 in Scotland. In 2001 The Colour Water Regulations Guide (copies available on Amazon etc.) was published and all water companies actively enforce the regulations. In these regulations there are large sections on backflow prevention. The Fluid Category identifies the level of contamination risk, with Category 3 identifying a slight health risk, Category 4 a significant risk and Category 5 a serious health risk. The photographs below show some obvious examples which could easily result in contamination of the local water supply. In relation to the dead animal in the tank, if it was not for the air gap between the water supply and the tank then pathogenic organisms could enter the supply. In the case of the photo of the pig in the water trough, a badly adjusted float valve has eliminated the air gap between the float valve and the water hence there is a risk of supply contamination.

A less obvious example is the humble washing machine. Clothes washing contaminates the water supplied to that machine. Soap powders and other chemicals are sufficient for the Fluid Category to be 3. In a house situation, the volumes, frequency of use and “dirtiness” of clothes mean the overall risk is Category 3. Admittedly soiled nappies are sometimes washed in a home machine but the use is probably infrequent. If the same machine is used in a commercial situation, the Fluid Category in many cases is 4. If the same machine is installed in a nursing home, where there may be incontinent residents and hence soiled sheets, the risk may be Fluid Category 5 which is the highest level of risk. So it is the use and not the appliance that determines the Fluid Category and therefore the backflow prevention required.

INTERESTING VIDEO RELATING TO BACK FLOW PREVENTION

CATEGORIES OF RISK AS DETAILED IN THE WATER REGULATIONS GUIDE

Fluid Category 1:

Wholesome water supplied by a water undertaker and complying with the requirements of regulations made under section 67 of the Water Industry Act 1991.

Fluid Category 2:

Water in fluid category 1 whose aesthetic quality is impaired owing to (a) A change in its temperature, or (b) The presence of substances or organisms causing a change in its taste, odour or appearance, including water in a hot water distribution system.

Fluid Category 3:

Fluid which represents a slight health hazard because of the concentration of substances of low toxicity, including any fluid which contains (a) ethylene glycol, copper sulphate solution or similar chemical additives, or (b) sodium hypochlorite (common disinfectants).

Fluid Category 4:

Fluid which represents a significant health hazard because of the concentration of toxic substances, including any fluid which contains (a) chemical, carcinogenic substances or pesticides (including insecticides and herbicides), or (b) environmental organisms of potential health significance.

Fluid Category 5:

Fluid representing a serious health hazard because of the concentration of pathogenic organisms, radioactive or very toxic substances, including any fluid which contains (a) faecal material or other human waste, or (b) butchery or other animal waste, or (c) pathogens from any other source.

EXAMPLES

Fluid Category 1:

Water supplied directly from a water main.

Fluid Category 2:

Mixing of hot and cold water supplies. Domestic softening plant (common salt regeneration). Drink vending machines in which no ingredients or carbon dioxide are injected into the supply or distributing inlet pipe. Fire sprinkler systems (without anti-freeze). Ice making machines. Water cooled air conditioning units (without additives).

Fluid Category 3:

Water in primary circuits and heating systems (with or without additives) in a house. Domestic washbasins, baths and showers. Domestic clothes and dishwashing machines. Home dialysing machines. Drink vending machines in which ingredients or carbon dioxide are injected. Commercial softening plant (common salt regeneration only). Domestic hand held hoses with flow controlled spray or shut-off control. Hand held fertiliser sprays for use in domestic gardens. Domestic or commercial irrigation systems, without insecticide or fertiliser additives, and with fixed sprinkler heads not less than 150mm above ground level.

Fluid Category 4:

- General: Primary circuits and central heating systems in other than a house. Fire sprinkler systems using anti-freeze solutions.

- House Gardens: Mini-irrigation systems without fertiliser or insecticide application; such as pop-up sprinklers or permeable hoses.

- Food Processing: Food preparation. Dairies. Bottle washing apparatus. Catering: Commercial dishwashing machines. Bottle washing apparatus. Refrigerating equipment.

- Industrial and Commercial Installations: Dyeing equipment. Industrial disinfection equipment. Printing and photographic equipment. Car washing and degreasing plants. Commercial clothes washing plants. Brewery and distillation plant. Water treatment plant or softeners using other than salt. Pressurised firefighting systems.

Fluid Category 5:

- General: Industrial cisterns. Non-domestic hose union taps. Sinks, urinals, WC pans and bidets. Permeable pipes in other than domestic gardens, laid below or at ground level, with or without chemical additives. Grey water recycling systems.

- Medical: Any medical or dental equipment with submerged inlets. Laboratories. Bedpan washers. Mortuary and embalming equipment. Hospital dialysing machines. Commercial clothes washing plant in health care premises. Non-domestic sinks, baths, washbasins and other appliances.

- Food Processing: Butchery and meat trades. Slaughterhouse equipment. Vegetable washing.

-Catering: Dishwashing machines in health care premises. Vegetable washing.

- Industrial and Commercial Installations: Industrial and chemical plant etc. Mobile plant, tankers and gully emptiers.

- Laboratories: Sewage treatment and sewer cleansing. Drain cleaning plant. Water storage for agricultural purposes. Water storage for firefighting purposes.

- Commercial Agricultural: Commercial irrigation outlets below or at ground level and/or permeable pipes, with or without chemical additives. Insecticide or fertiliser applications. Commercial hydroponic systems.

BACKFLOW PREVENTION DEVICES

European / UK Classification | Suitable Backflow Prevention Device |

Fluid Category 5 | Air Gap - AA, AB / Pipe Interrupter – DC |

Fluid Category 4 | RPZ – BA / Pipe Interrupter - DB |

Fluid Category 3 | Double Check - ED |

Fluid Category 2 | Single Check – EB |

Fluid Category 1 | No device required |

The first letter for the "Prevention Device" denotes the family i.e. A = air gap, D = pipe interupter, E = check valve. The second letter denotes the type e.g. AD = air gap with injector, DC = pipe interupter with permanent atmospheric vent, EA = verifiable single check valve.

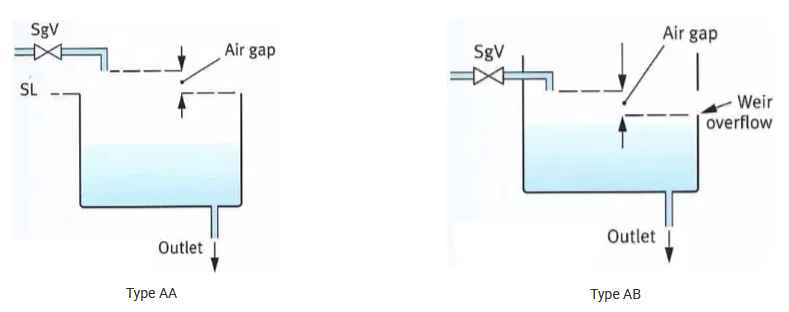

AA – Air gap with unrestricted discharge

This means a non-mechanical backflow prevention arrangement of water fittings where water is discharged through an air gap into a receptacle which has at all times an unrestricted spill over to the atmosphere.

AB – Air gap with weir overflow

This means a non-mechanical backflow prevention arrangement of water fittings complying with Type AA, except the air gap is the vertical distance from the lowest point of discharge orifice which discharges into the receptacle, to the critical water level of the rectangular weir overflow.

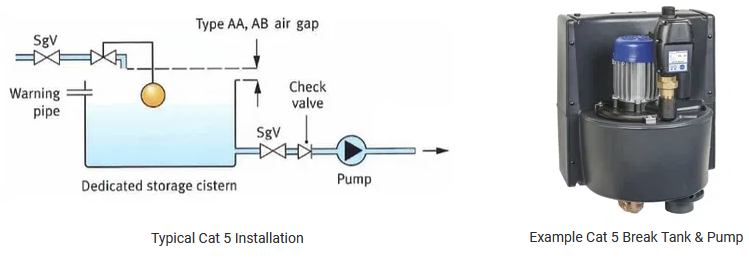

In many instances a Cat 5 protection device incorporates a ball valve, a tank and a pump to get the pressure back up. Because the protection is gained through having an air gap, the device is 100% safe as it is not relying on a mechanical device such as a check valve.

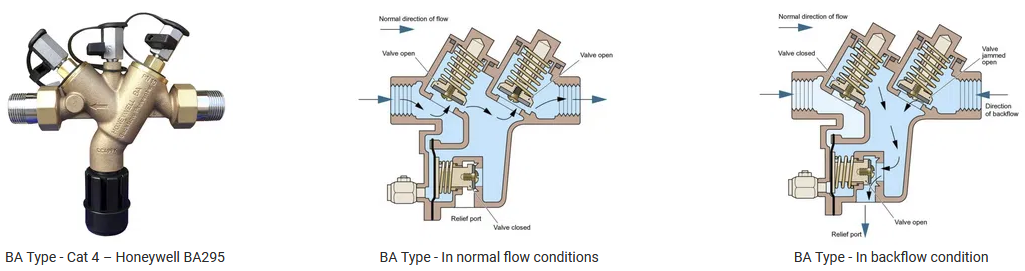

BA – Verifiable backflow preventer with reduced pressure zone

This means a verifiable mechanical backflow prevention device consisting of an arrangement of water fittings with three pressure zones with differential obturators and that will operate when potential backflow conditions obtain or there is a malfunction of the valve.

Click on the link to view the wras-approved-installation-method-for-rpz-valves which is approved by the water undertakers (water suppliers) under Regulation 4 of the Water Supply (Water Fittings) Regulation/Scottish Water Byelaws.

BA devices require resilient seat isolating valves, an appropriate strainer (100 micron) such as the Honeywell F76S Fine Water Filter with Backwash Control and correct installation clearances. The assembly should be in a tamper-proof environment or installed in a cabinet. Also because they are a mechanical device they require annual testing.

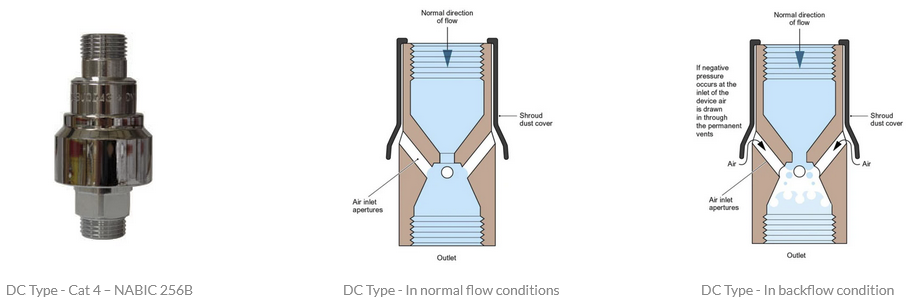

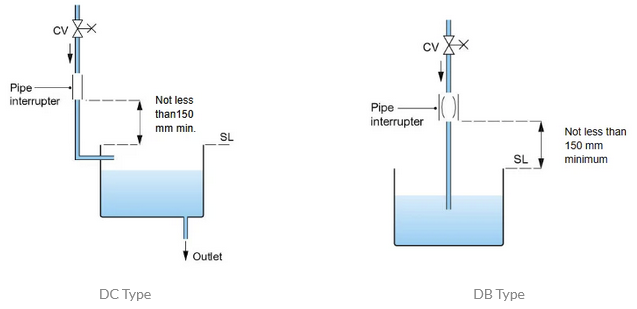

DC – Pipe interrupter with permanent atmospheric vent

This means a non-mechanical back-flow prevention device with a permanent unrestricted air inlet, the device being installed so that the flow of water is in the vertical downward direction.

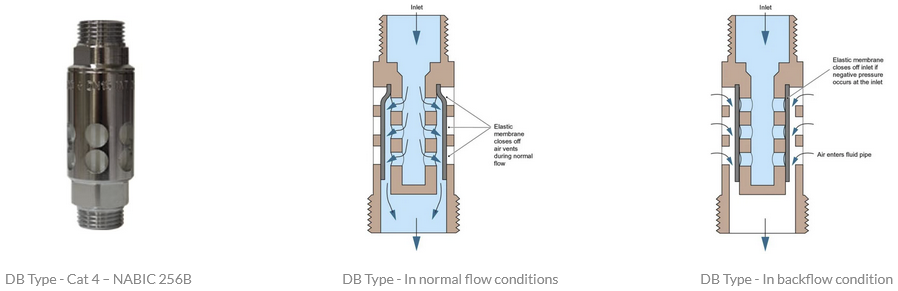

DB – Pipe interrupter with atmospheric vent and moving element

Means a mechanical backflow prevention device with an air inlet closed by a moving element when the device is in normal use but which opens and admits air if the water pressure upstream of the device falls to atmospheric pressure, the device being installed so that the flow of water is in a vertical downwards direction.

DB and DC devices cannot have a valve or restriction on its outlet. If you were using them with a hose pipe then you would have the tap, then the pipe interrupter, and then the hose. If you put the device before the tap then with the tap closed, water would come out of the sides of the pipe interrupter since you have created a back pressure.

ED – Non-verifiable double check valve

Means a non-verifiable mechanical back-flow prevention device consisting of two single check valves in series, which will prevent water to flow from upstream to downstream but not in the reverse direction.

EB – Non-verifiable single valve

Means a non-verifiable mechanical back-flow prevention device which will permit water to flow from upstream to downstream but not in the reverse direction.

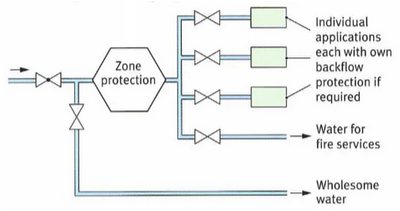

ZONED PROTECTION AND POINT OF USE PROTECTION

Zone protection is often used in industrial, chemical or medical premises to group particular areas of activity and risk, in addition to individual back-flow protection at points of use.

Example

A dishwasher and a washing machine in a non-house installation should be fed individually with their own back-flow prevention device (Point of Use protection). The reason is because if the dishwasher was on its final rinse, whilst the washing machine was full of significantly harmful substances (e.g. soiled clothing), when a negative pressure caused back-flow to occur. The fluid in the clothes washer could contaminate the culinary items in the dishwasher. Zone protection alone would prevent it spreading any further but would not prevent contamination between the two machines.

BACKFLOW PREVENTION DEVICE TESTING

The Water Supply (Water Fittings) Regulations 1999, do not give give any specific requirements for the maintenance of a product. You should therefore liaise with the manufacturer / stockist of the product to ask what they recommend.

For RPZ valves, the UK Water Companies have issued an wras-approved-installation-method-for-rpz-valves. This requires the RPZ valve to be tested at least annually or at more frequent intervals as specified by the Water Supplier.The valve must be tested and commissioned by a Water Industry Approved RPZ Tester. A competent person can install the valve but it MUST be tested and commissioned by a Water Industry Approved RPZ Tester.