SCREWED CONNECTIONS

The most common screwed connections are BSP & NPT.

BSP

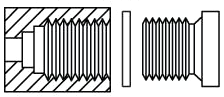

BSP stands for British Standard Pipe and is a British standard. There are two types of BSP threads – parallel (BSPP) and taper (BSPT). BSPP is popular in the UK, Europe, Asia, Australia, New Zealand and South Africa. BSPT is popular in China and Japan. Both threads have the same pitch, angle (55 degrees) and shape (rounded peaks and valleys).

BSPP

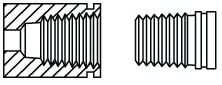

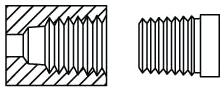

BSPTNPT stands for National Pipe Thread and is an American standard. NPT threads are usually taper. Both threads have the same pitch, angle (60 degrees) and shape (flat peaks and valleys). They can be used without sealant due to the taper but this also depends upon the medium. One potential issue is if you over-tighten stainless to stainless threads then they can gall causing damage and making them very difficult to separate.

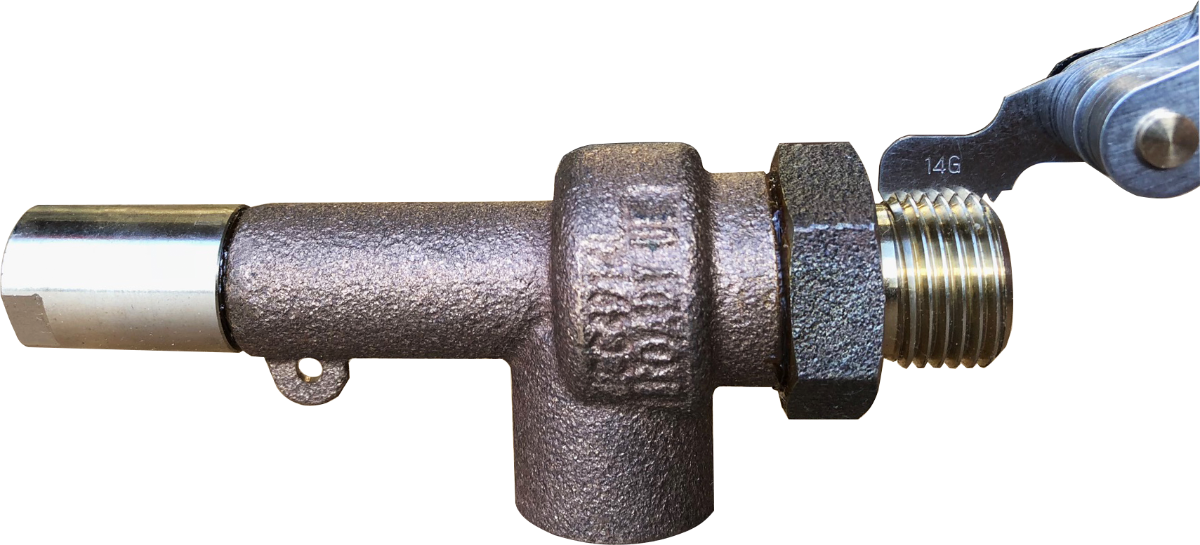

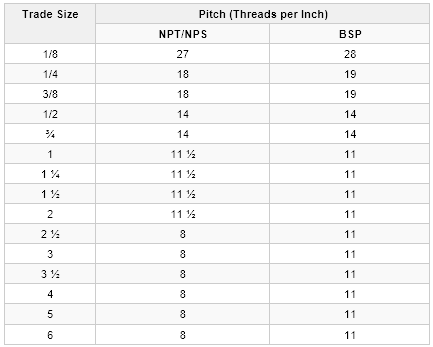

NPTBSP and NPT threads are not cross compatible due to the differences in the thread forms hence should not be combined. One way you can determine which type you have is to use a thread gauge or simply count the number of threads in 1” (25.4mm). Counting the threads can be tricky however as the number of threads is the same for 1/2” to ¾” and almost identical for 1” to 2” (see the table below).

Thread gauge showing 14 threads per inch

Table showing threads per inch for various sizesTaper threads are usually sealed on the thread using PTFE tape or liquid pipe sealant. Parallel threads are usually sealed using an O-ring seal or bonded washer (i.e. dowty washer). You can put a taper thread into a parallel hole but it can be harder to seal since it is only the higher threads that are tight in the hole and hence it is not a recommended practice for high pressures. If you put a parallel thread into a taper hole then you are only likely to get a few turns before it will wedge in. Again this is harder to seal and the valve is only being held in by a few threads which could be dangerous at high pressures.

FLANGED CONNECTIONS The most common flange connections are ANSI which is an American standard, PN / DIN which is a European standard and JIS/KS which is a Japanese / Korean standard. In the UK you will find both ANSI and PN in use but you may also come across the old British BS10 Table D, E, F & H flanges.

- ASA150, 300, 400, 600, 900, 1500, 2500

- Metric PN6, 10, 16, 25, 40

- BS10 Table D, E, F, H

We have a good article about these flange types titled

“Flanges, Gaskets & Bolts” available from the technical menu above.

One flange type not mentioned in this article is the APV FGN 1 flange which can be found in process engineering applications where cleaning and bacteriological safety are imperative. The design also prevents the connection being over tightened and eliminates the mechanical load on the seal.

SPECIAL CONNECTIONS There are various other connection types commonly found in hygienic / pharmacy applications.

Clamp Connections - DIN 11850

- ISO 1127

- ISO 2037

- DIN 11864 T3 Type A and B

- DIN 11866-A

- DIN11866-B

- DIN11866-C

Threaded / Conical Connections

- DIN11851

- DIN 11850

Aseptic Male / Female Connections - DIN 11864 T1 Type A and B

- DIN 11850

- DIN EN ISO 1127

- ISO 2037

- BS 4825-1